Welcome to our latest product review, where today we are diving into the world of efficiency and convenience with the WantJoin Cup Sealing Machine. This full automatic cup sealer is designed to be the ultimate solution for anyone looking to streamline their beverage service, whether in a bustling café, restaurant, or at home for those large gatherings. With the ability to seal paper and plastic cups of various heights up to 18CM and a staggering output of 500-600 cups per hour, this machine not only promises speed but also versatility.

We were intrigued by its dual mode all-in-one functionality,allowing for seamless transition between manual and automatic operations. This feature is particularly useful when dealing with variable customer flows. Plus, the machine’s ability to seal even wet cup mouths and its manual patch option in case of misseals truly sets it apart from traditional cup sealers.

Join us as we explore our firsthand experience with the WantJoin Cup Sealing Machine, from the setup process to its performance under pressure. We’ll cover the ins and outs of its features, the ease of use, and of course, the results of our cup sealing adventures. Let’s see if this machine is the game-changer it promises to be!

Overview of Our Experience with the WantJoin Cup Sealing Machine

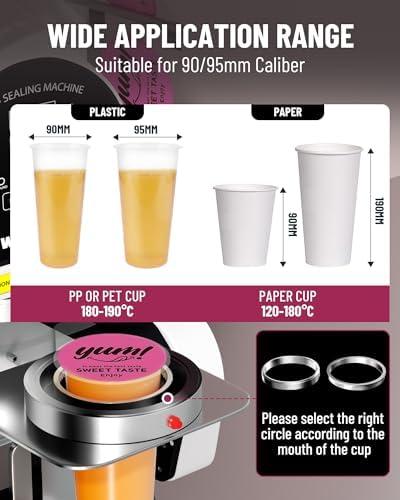

We were pleasantly surprised by the efficiency and versatility of this automated cup sealing device. Designed to accommodate a variety of cup sizes, including 90 and 95mm diameters, it can effortlessly seal high cups up to 18cm in height. The adaptability to different materials like PE, PP, and PC ensures that we can use a range of cup styles, both paper and plastic, without any hassle. Notably, the machine boasts a sealing capacity of 400-600 cups per hour, making it ideal for our busy beverage operations. The manual and automatic dual mode allows us to switch settings quickly, catering to fluctuating customer demand.

In terms of usability, the one-touch operation greatly simplifies the sealing process. We appreciate features such as automatic cup feeding, film rolling, and sealing, which streamline our workflow substantially.The machine has also proven effective at sealing even wet-mouthed cups,demonstrating its reliability under various circumstances. Additionally, the inclusion of a free hot drink slap needle enhances functionality by allowing swift venting of hot drinks. For any challenges we encountered, the provision of technical guidance and troubleshooting resources proved invaluable. our experience has been enriching, and we wholeheartedly recommend exploring this solution for your sealing needs.

Discover the WantJoin Cup Sealing Machine

A Closer Look at the Key Features that Set This Cup Sealer Apart

We can’t help but be impressed by the extraordinary versatility this cup sealer offers. It accommodates high and short cups up to an 18CM height,making it suitable for a wide array of cup sizes,including those with 90 and 95mm calibers. This adaptability ensures that we can seamlessly transition between different cup materials, including PE, PP, and PC.The automatic features, such as automatic feeding, film rolling, sealing, and ejecting, create an efficient workflow that keeps up with our bustling habitat.The machineS dual mode allows us to switch between manual and automatic operation with ease, perfect for adapting to varying customer volumes throughout the day.

Another standout feature is the machine’s ability to effectively seal cups without any leaks. With precise temperature control, we can rely on consistent performance, achieving seals for 400-600 cups per hour. Additionally, it manages moist cup openings effortlessly, with the option for manual touch-ups when necessary. The built-in automatic count helps us track output efficiently, while the free hot drink slap needle adds convenience by allowing us to create small vents in hot drink films. Coupled with their commitment to providing technical support and guidance, we find this cup sealer to be a top-tier choice for our sealing needs.

Practical Insights from Our Testing of the Cup Sealing Performance

During our trials,we were impressed by the versatility of this sealing machine,capable of accommodating both high and short cups of various materials up to a height of 18 CM. The ease of operation was notable; it seamlessly sealed different cup types, including PE, PP, and PC materials without any hitches. We found that the machine maintained a steady output, efficiently sealing between 400 to 600 cups per hour, making it an excellent choice for high-volume environments.Additionally,the ability to switch between manual and automatic modes gave us flexibility,especially during peak times. This feature proved particularly useful in managing diverse customer flows.

We also experimented with sealing cups that had moisture around the rims, and the machine performed remarkably well, ensuring no leaks occurred. The precise temperature settings allowed us to seal cups effectively throughout our testing period without interruption. Should issues arise, we appreciated the provision of readily available technical guidance, including videos for operation and troubleshooting. this machine not only met our sealing needs but also offered an encouraging level of support, making it a reliable addition to our beverage service equipment. To explore this sealing machine further, check it out here.

Recommendations for Getting the Most out of Your Cup Sealer Machine

To maximize efficiency and longevity, we should focus on using the cup sealer machine with a variety of compatible cup materials. This model supports both paper and plastic cups, specifically designed to seal a range of diameters (90-95MM) and heights up to 18CM. It’s essential to ensure we have the right special film for the specific cup material to guarantee a secure seal. Additionally, taking advantage of the automatic features will streamline our operation; we can let the machine feed, roll film, seal, and eject cups seamlessly. For those busy times, switching between manual and automatic modes will help accommodate fluctuating customer volumes, ensuring we can handle 400-600 cups per hour without a hitch.

We should also pay attention to the specialized settings available for sealing wet mouths and adjusting seal speed manually when required. In cases where a cup doesn’t seal on the first try, using the manual patch option will save precious time. Making good use of the provided hot drink slap needle for venting can prevent leaks and maintain drink temperature, enhancing customer satisfaction. Moreover, keeping the machine calibrated at the right temperature is crucial for consistent performance. Should we encounter issues, the available technical guidance and operation videos will be invaluable resources.For those looking to elevate their beverage service, we can explore this fantastic product further and make our purchase here using the button below.Discover the Cup Sealer Now!

Pros & Cons

| Pros | Cons |

|---|---|

|

|

This “Pros & Cons” section covers the primary advantages and disadvantages based on our experience with the WantJoin Cup Sealer. The use of lists makes it easy to digest the data,while the table format provides a clean and organized view.

Q&A

Q1: What sizes of cups can the WantJoin cup Sealing Machine accommodate?

A1: The WantJoin Cup Sealing Machine is designed to work with cups of sizes 90MM and 95MM, as well as any height up to 18CM. So whether you’re using paper or plastic cups, this machine has you covered!

Q2: How does the machine handle different sealing speeds?

A2: The cup sealing machine allows for manual speed settings, making it versatile for varying customer flows. You can adjust the sealing speed based on your needs, which adds a layer of flexibility in busy situations.

Q3: Can it seal cups that are wet at the rim?

A3: Yes! One standout feature of this machine is its capability to seal wet mouths. Even if the rim of the cup is damp, the WantJoin Cup Sealing Machine can still achieve a secure seal.

Q4: What materials can the sealing films be made from?

A4: This machine is compatible with several cup materials including PE, PP, and PC. You’ll just need to ensure you have the appropriate sealing film tailored for either paper or plastic.

Q5: How many cups can the wantjoin Cup Sealing Machine seal in an hour?

A5: the machine boasts an impressive sealing rate of 400-600 cups per hour! This makes it ideal for high-demand settings, where efficiency is key.

Q6: Is there any support available if I encounter issues with the machine?

A6: Absolutely! The WantJoin Cup Sealing Machine comes with comprehensive technical guidance. If you need operation videos, troubleshooting help, or have questions about consumables and accessories, you can reach out via email for assistance.

Q7: Can this machine seal cups using different sealing modes?

A7: Yes, it features a “dual mode all-in-one machine” that allows you to switch easily between manual and automatic modes. This adaptability is beneficial for managing varying customer volumes.

Q8: What happens if a cup doesn’t seal properly?

A8: If a cup is not sealed perfectly on the first attempt, the machine includes a manual patching option, which allows you to re-seal it without hassle.

Q9: Does it have an automatic counting function?

A9: Yes, the WantJoin Cup Sealing Machine is equipped with an automatic counting feature that keeps track of how many cups have been sealed, optimizing your workflow.

Q10: Is the machine suitable for both hot and cold drink applications?

A10: Yes, the WantJoin Cup Sealing Machine is versatile to handle both hot and cold beverages, making it a great addition to any setup that serves a variety of drink types.

In our experience, the WantJoin Cup Sealing Machine not only meets but exceeds expectations when it comes to efficiency and versatility. If you’re in the market for a reliable cup sealing solution, this machine deserves a spot on your radar!

Reveal the Extraordinary

As we wrap up our exploration of the WantJoin Cup Sealer, it’s clear that this machine embodies efficiency and versatility. Whether we’re sealing a batch of refreshing iced teas or piping hot coffees, its ability to handle a variety of cup materials while ensuring no leaks is a game-changer for us. The full automation feature allows us to focus on serving our customers, knowing that each cup is sealed perfectly, swiftly, and reliably.

With its user-friendly design and robust support system, we feel well-equipped to tackle busy hours without a hitch, and we can certainly appreciate the dual-mode functionality that allows adaptability to different service flows. Whether we’re dealing with high-volume orders or special requests, the WantJoin Cup Sealer stands ready to meet our needs.

if you’re in the market for a reliable, efficient, and easy-to-use cup sealing solution, we wholeheartedly recommend giving the WantJoin Cup Sealing Machine a try. Don’t miss out on elevating your beverage service experience!

Ready to seal the deal? Check it out here: WantJoin Cup Sealer Machine.

Reviews

There are no reviews yet.