Welcome to our latest product review, where we dive into the world of efficient beverage service with the WantJoin Cup Sealing Machine! As enthusiasts of innovative kitchen technology, we’ve had the opportunity to put this full automatic cup sealer to the test, and we’re excited to share our firsthand experience with you. Designed for high-volume operations,this machine promises impressive sealing capabilities for a variety of drinks,including bubble tea,coffee,and even hot beverages.With its 90/95mm compatibility and the ability to seal up to 650 cups per hour, the WantJoin machine aims to transform the way we serve drinks in commercial settings. Whether you’re running a bustling cafe or a lively bubble tea shop, the versatility and precision of this electric sealer positions it as an essential tool for enhancing customer satisfaction and streamlining operations.

Join us as we explore the features, versatility, and performance of the WantJoin Cup Sealing Machine.From its innovative design to its user-friendly controls, we’re here to uncover whether this machine truly lives up to its promises and is worthy of a place in your establishment.Let’s seal the deal on the ins and outs of this impressive gadget!

Overview of the WantJoin Cup Sealing Machine Experience

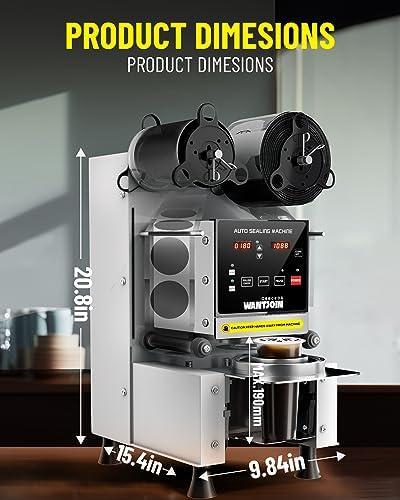

This compact and efficient machine is engineered to handle a variety of cup sizes and materials, making it a versatile addition to our beverage service toolkit. We appreciate its 90 or 95mm compatibility and the ability to work seamlessly with different cup heights, up to 18cm. The adaptability to both plastic and paper cups, using only the appropriate sealing film, ensures that we can package a diverse array of beverages. with an impressive capacity to seal between 500 and 650 cups per hour, it has dramatically improved our workflow during peak service hours, allowing us to keep pace with customer demands without sacrificing quality.

Additionally,the machine’s dual mode operation offers both manual and automatic sealing options,making it easy to adjust according to our specific needs. Even in challenging scenarios, such as sealing cups with moist rims, it excels thanks to its manual speed adjustments. The built-in capability to perform manual patches for missed seals has been a valuable feature, ensuring that every cup leaves our shop perfectly sealed. We also find the included hot drink vent needle especially useful, as it allows us to release steam without compromising the seal. our experience with this cup sealing solution has been enhanced significantly, coupled with excellent customer support for any technical assistance we may need.

For those interested in streamlining their beverage sealing process, we highly recommend checking this machine out.Explore it here!

Key Features That Enhance Our Brewing Efficiency

One of the standout attributes of this machine is its versatile compatibility, which allows us to seal both 90mm and 95mm cups of varying heights (up to 18cm/7.1in). This flexibility extends to the materials we can use, as it effectively works seamlessly with paper, PE, PP, and PC plastic cups. we can efficiently seal batches of 90 cups at a time, which is perfect for high-traffic periods in our beverage establishment.The ability to effortlessly switch between materials empowers us to cater to a diverse menu without the hassle of incompatible supplies.

Moreover, the precision sealing capabilities ensure that we experience zero leaks, which is crucial for maintaining the quality of our beverages. The machine’s capacity to seal between 500-650 cups per hour with consistent temperature settings elevates our operational efficiency significantly. we appreciate the manual and automatic modes, which provide adaptability based on customer flow, preventing bottlenecks during busy times. For those tricky moments when a seal might fail, the manual patching option ensures that every cup is properly sealed, while the included hot drink vent needle allows for steam release, preventing overflow or spillage during the sealing process. Our ability to optimize output has never been easier.

In-Depth Insights into Performance and Usability

When it comes to performance, we are truly impressed with the sealing capabilities offered by this machine. It can seal between 500-650 cups per hour,making it an ideal solution for high-traffic environments such as milk tea shops and cafes. The device operates with a dual mode feature,allowing us to toggle between manual and automatic settings based on changing customer demands. This versatility not only enhances efficiency but also ensures that we can maintain consistent sealing quality under varying conditions. Notably, the ability to accommodate both 90mm and 95mm cups, paired with a sealing range for heights up to 7.1 inches, provides immense flexibility for our beverage offerings.

Usability is another strong aspect where this cup sealer excels. The automated operation means that staff only need to place the cup in the machine, and it takes care of the rest—feeding, sealing, and ejecting the cups with precision. It even has built-in manual speed adjustments, allowing us to seal cups with moist rims without any hassle. To further enhance our sealing experience,the inclusion of a vent needle provides controlled steam release during the sealing process,minimizing the risk of leaks and ensuring every cup is perfectly sealed. Not to forget, access to extensive technical support ensures we can maintain optimal operation, making this an indispensable tool for our business.

Discover the Ultimate Cup Sealer

Our Recommendations for Maximizing the Cup Sealing Machines Potential

To elevate the performance of this sealing machine,we should first take advantage of its versatile compatibility. It’s built to accommodate 90 or 95mm cups of various heights,making it essential for us to choose the right cup material. We recommend using specialized films tailored to plastic or paper cups made from PE, PP, or PC. This choice will not only maximize sealing efficiency but also ensure that we can cater to a wider clientele by adapting to different beverage types. Additionally,taking the time to manually adjust the speed settings may prove beneficial,especially when handling cups with moist rims,ensuring a reliable seal every time.

Another key aspect we can focus on is the precision sealing technology. With the capability of sealing 500-650 cups per hour, it’s crucial that we maintain optimal temperature settings. By frequently monitoring the output and utilizing the automatic counting feature, we can achieve consistent quality in our sealing process. In high-traffic periods, switching between manual and automatic modes allows for adaptability aligned with customer demand.Moreover, leveraging the comprehensive technical support available will help keep our operations uninterrupted, empowering us to provide an excellent customer experience. Explore more and transform your beverage service by visiting here.

Pros & Cons

| Pros | Cons |

|---|---|

|

|

This “Pros & Cons” section for the WantJoin Cup Sealing Machine review provides a balanced view of the product’s strengths and weaknesses, using a clear layout and bullet points for easy readability.

Q&A

Q1: What types of cups are compatible with the WantJoin Cup Sealer?

A1: The WantJoin Cup Sealer is designed to accommodate both 90mm and 95mm cups of various heights, up to 18cm (7.1 inches). It works exceptionally well with cups made from different materials, including paper and plastic (PE, PP, and PC). This versatility makes it suitable for a wide range of beverages, from milk tea to coffee.

Q2: How does the machine handle cups with moist rims?

A2: We found that the WantJoin Cup Sealer is quite adaptable in challenging sealing conditions.The machine allows for manual speed adjustment, which helps in sealing cups with moist rims effectively. Additionally, if there happens to be a missed seal, it offers manual patching capabilities, ensuring that every cup is perfectly sealed.

Q3: What is the sealing capacity of this machine?

A3: This automatic cup sealer is impressive in its capabilities, sealing between 500 to 650 cups per hour. This high output is especially beneficial during peak hours, allowing us to serve our customers efficiently without delays.

Q4: Is it easy to switch between manual and automatic modes?

A4: Absolutely! The WantJoin Cup Sealer features a ”Dual Mode All-in-one” option that allows easy switching between manual and automatic modes. This seamless transition helps us adapt to fluctuating customer demands, making our operations more efficient.

Q5: Does the machine require special film for sealing?

A5: Yes, the WantJoin Cup Sealer requires specialized sealing film that is compatible with the type of cup material being used (paper or plastic).It’s crucial to ensure you have the correct film for optimal sealing performance.

Q6: What support does WantJoin provide for this machine?

A6: We appreciate the comprehensive technical support from WantJoin. They offer a variety of resources, including operation videos, troubleshooting tutorials, and guidance on obtaining consumables and accessories. if we ever have questions or need assistance, their dedicated support team is just an email away.

Q7: Does the machine have features for steam release?

A7: Yes, the WantJoin Cup Sealer comes with a complimentary hot drink vent needle. This handy feature allows for controlled steam release during the sealing process, which can prevent potential mishaps and ensures a perfect seal every time.

Q8: How does the machine improve our overall efficiency?

A8: By automating the sealing process, the WantJoin Cup Sealer minimizes operational bottlenecks in our beverage shop.Its high sealing speed and automatic counting capabilities allow us to focus more on serving customers while maintaining consistent quality,enhancing overall efficiency and customer satisfaction.

Q9: Can we easily monitor daily output with this machine?

A9: Yes, the machine has an automatic counting feature that keeps track of our daily output effortlessly. This aspect helps us manage inventory and understand our productivity trends better.

Q10: Is the WantJoin cup Sealer easy to clean and maintain?

A10: We found that maintenance is straightforward, thanks to the machine’s design. regular cleaning and ensuring the sealing area is free from debris go a long way in maintaining optimal performance. The user manual provides additional insights into cleaning routines and upkeep to prolong the machine’s lifespan.

If you have more questions about the WantJoin Cup Sealer, feel free to reach out to us in the comments below! We’re happy to share our experiences and help you find the right sealing solution for your needs.

Achieve New Heights

As we wrap up our journey with the WantJoin Cup Sealing machine, it’s clear that this full automatic cup sealer is a game changer for anyone in the beverage business. with its versatile compatibility, impressive sealing speed, and user-friendly features, we’ve found that it not only meets our demands but elevates our operations to new heights. Whether we’re sealing bubble tea,milk coffee,or any other delicious concoction,we can trust this machine to deliver precision,efficiency,and reliability.

in a bustling surroundings where customer satisfaction is paramount, the WantJoin Cup Sealer stands out with its dual mode operation and adaptability in special conditions. We’ve appreciated the thoughtful design that allows us to tackle any sealing challenge thrown our way.Plus,with robust technical support readily available,we feel confident in our investment and ready to tackle whatever comes next.If you’re on the lookout for a reliable partner to enhance your beverage sealing experience, the WantJoin Cup Sealing Machine could very well be the solution you need. Explore the possibilities and take your business to the next level by checking out the product for yourself.

Discover sealing perfection here: WantJoin Cup Sealer on Amazon.

Reviews

There are no reviews yet.