In the bustling world of beverage service,efficiency and quality are paramount,especially when it comes to satisfying customers at a high volume. We recently had the opportunity to dive into the ins and outs of the WantJoin Cup Sealing Machine, a full automatic cup sealer that promises to revolutionize how we seal cups for bubble milk tea, coffee, and more. With a staggering capacity to seal 500-600 cups per hour, combined with an impressive digital control LCD panel, this machine claims to be the perfect solution for those of us managing busy cafes, food trucks, or bubble tea shops.

In this review, we’ll share our firsthand experience with this versatile sealer, exploring its notable features, ease of use, and how it holds up under pressure. From its ability to seal both paper and plastic cups to the convenience of automatic operation and technical support, we’ll cover everything you need to know about whether the WantJoin Cup Sealing Machine deserves a spot on your counter. Join us as we unpack the performance and practicality of this powerful tool, designed to keep pace with our ever-growing customer demand.

Overview of Our Experience with the WantJoin Cup Sealing Machine

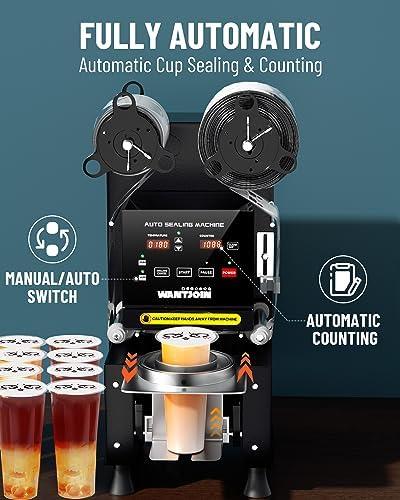

Our experience with this automatic cup sealing machine has been quite impressive. The versatility of being able to seal both paper and plastic cups made it an ideal choice for our beverage needs. We appreciated the fully automatic operation,which includes automatic feeding,sealing,ejecting,and counting the number of cups sealed each day.With a sealing speed capable of handling 500-600 cups per hour, it considerably streamlines our operations during peak hours. The inclusion of two 90mm fitting rings was an added bonus, allowing us to adapt to various container sizes, and the option to manually patch any sealing issues proved to be useful during some of our busier shifts.

Notably, one of the standout features for us was the machine’s capability to seal wet cup mouths without leaking, effectively maintaining product quality. The temperature settings are accurate and customizable to ensure optimal sealing conditions, which was crucial for beverages served in different materials such as PE, PP, and PC. The dual mode functionality—switching between manual and automatic—has made it easier for us to adjust according to the customer traffic, ensuring maximum efficiency.For those looking to enhance their beverage business, we highly recommend exploring this efficient solution. Check it out now!

Discover the Cup Sealing Machine

Key Features That Enhance Our Beverage Sealing Process

In-Depth Insights on Performance and Usability

The performance of this cup sealing machine stands out with its capability to seal between 500 to 600 cups per hour, making it an excellent choice for high-demand environments such as bubble tea shops or coffee outlets. We appreciate the dual mode functionality, which allows us to switch between manual and automatic settings with ease.this is especially useful during peak hours when customer demand fluctuates. Additionally, the machine is compatible with a variety of cup materials, including PE, PP, and PC; this versatility ensures that we can adapt to different product offerings without needing to invest in multiple machines. The presence of two fitting rings for different cup sizes (90mm and 95mm) enhances the usability, allowing us to work seamlessly with both types of cups.

In terms of usability, the automatic features of this machine simplify our workflow significantly.It feeds the cup, rolls the film, seals it, and ejects it—all without requiring manual intervention. This not only allows us to maintain a consistent sealing temperature but also minimizes the risk of human error during the sealing process. Another innovative aspect is the inclusion of a slap needle for hot drinks, which helps us manage any excess pressure that may build up. The presence of a digital control LCD panel further facilitates ease of operation, allowing us to monitor the number of cups sealed throughout the day. To enhance our experience, the manufacturers also provide access to helpful instructional videos, ensuring we have the guidance needed for troubleshooting and optimal operation.

Our Recommendations for Optimal Use and Maintenance

To ensure we maximize the efficiency and longevity of our cup sealing machine, we recommend following a few key maintenance and operational tips. We should always use the correct sealing films: PP sealing film for PP and paper cups and PET sealing film for PET cups. Additionally, it’s crucial to regularly check and clean the fitting rings to prevent residue buildup that can affect sealing performance. When adjusting settings or handling special circumstances, such as a wet cup mouth, we should refer to the detailed instructions provided directly on the machine. This ensures we get the timing, temperature, and sealing pressure just right, which will maintain a leak-proof seal.

Furthermore, leveraging the machine’s automatic functionality is vital for our busy environments. We can take advantage of the dual mode all-in-one operation, allowing us to switch between manual and automatic seals with ease based on our customer flow. Regularly monitoring the machine’s automatic counter will help us keep track of the number of cups sealed daily, enabling better inventory and supply management. Lastly, don’t hesitate to utilize the technical guidance offered for troubleshooting or operation video needs, ensuring that we optimize our use and handle any issues promptly.

Pros & cons

As we dive into the functionality of the WantJoin Cup sealing Machine, we find it essential to evaluate both its strengths and areas that could be improved. Here’s a rapid rundown of the pros and cons based on our extensive review.

| Pros | cons |

|---|---|

|

|

The wantjoin Cup Sealing Machine certainly shines in efficiency and automation, making it an excellent choice for busy beverage shops. However, potential buyers should weigh the initial learning curve and ongoing maintenance needs against these benefits to determine if it meets their sealing requirements.

Q&A

Q1: What types of cups can the WantJoin Automatic Cup Sealer accommodate?

A1: The WantJoin Cup Sealer is quite versatile! It can handle both paper and plastic cups, and is compatible with PE, PP, and PC materials.You can seal cups with diameter calibers of 90mm or 95mm, with heights ranging from 9cm to 19cm.It even comes with two fitting rings for 90mm cups to enhance compatibility.

Q2: How fast is the cup sealing process with this machine?

A2: we found that the WantJoin Cup Sealer can seal an impressive 500 to 600 cups per hour! this speed is a game-changer, especially for busy bubble tea shops or coffee stations.

Q3: Can the machine handle wet cups or faulty seals?

A3: Absolutely! One of the standout features of this machine is its ability to seal wet cup rims. If a seal doesn’t go through on the first try, there is a manual patch option available. Plus, it comes with a hot drink slap needle that allows you to create a vent in the sealing film for hot beverages, preventing any spillage.

Q4: What is the setup process like? Is it user-kind?

A4: Setting up the WantJoin Cup Sealer is straightforward. After placing the cup in the designated area, the machine does the rest—feeding, rolling film, sealing, and ejecting are all handled automatically. It also features an LCD panel for easy control, and if you ever run into issues, there are operation and troubleshooting videos available for assistance.

Q5: Is this machine suitable for businesses with varying customer flows?

A5: Yes, it is indeed! The WantJoin Cup Sealer has a dual mode that allows you to switch between manual and automatic sealing, adapting to different customer volumes effortlessly. This feature is particularly useful during peak hours to ensure efficiency.

Q6: Are there any specific film requirements based on the type of cups?

A6: Yes, there are! For PP cups and paper cups, you need to use PP sealing film, while PET cups require PET sealing film.This ensures that you get the best seal quality for your cups, so be sure to use the appropriate materials for optimal performance.

Q7: What should I do if the machine doesn’t recognize the cup alignment?

A7: If you encounter any issues with cup recognition, just refer to the sticker instructions located on the right side of the machine. It provides guidance on how to adjust the setup for proper alignment. The sensor’s red light will indicate when everything is aligned correctly.

Q8: What kind of customer support is available if we have questions?

A8: The support from WantJoin is comprehensive. They offer all-time technical guidance, and you can reach out for operation videos, troubleshooting help, or inquiries about consumables and accessories. Their customer service is there to assist with any equipment concerns you may have.

We hope this Q&A has clarified any doubts you might have about the WantJoin Automatic Cup Sealer! If you have more specific queries, feel free to reach out to us or the manufacturer for assistance.

Seize the Opportunity

Our experience with the WantJoin Automatic Cup Sealer has been nothing short of impressive. Whether we are operating in a bustling bubble tea shop during peak hours or preparing hot drinks for customers on the go, this versatile machine has proven itself as an invaluable asset. Its ability to seamlessly seal a variety of cup sizes and materials, coupled with its user-friendly digital controls, ensures that we can maintain efficiency without sacrificing quality.

With a speed that reaches an impressive 500-600 cups per hour and the capability to adapt to varying operating conditions, it truly stands out as a solution for any beverage business aiming to boost productivity. Plus, the added bonus of comprehensive technical support ensures we feel secure in our investment, no matter the challenges we face.

If you’re looking to elevate your drink service and seal your success, we wholeheartedly recommend giving the WantJoin Automatic Cup Sealer a try. For those ready to make a purchase and bring this remarkable machine into your café or shop, simply click the link below.

Reviews

There are no reviews yet.